Water Desalination System

Home » Water Desalination System

A desalination device, also known as a reverse osmosis (RO) system, is a filtration method that employs a thin, semi-permeable membrane with tiny pores to enable pure water to pass through. In this article, you will learn about :

- Definition of water desalination (reverse osmosis)?

- Types of water desalination

- Types of home water desalination

- Types of industrial water desalination

- Technical specifications of a water desalination

- All kinds of water desalination brands

What is an RO water purifier?

A desalination device, also known as a reverse osmosis (RO) system, is a filtration method that employs a thin, semi-permeable membrane with tiny pores to enable pure water to pass through.

Reverse osmosis produces ultra-clean water for drinking water systems, industrial steam boilers, food and beverage processing, cosmetics, pharmaceutical manufacturing, seawater desalination, and many other applications. Desalination technology has been recognized for over a century and has been on the market since the 1960s.

Types of water desalination

- Home water desalination

- Industrial water desalination

- Semi-industrial water desalination

- Seawater desalination

- Thermal water desalination

Home water desalination

A home water desalination produces ultra-pure water for home use and is a comprehensive water purification system that includes filters, pumps, and a central reverse osmosis membrane.

This membrane contains tiny pores that only allow pure water to pass through. Water passes through the membrane under pressure, while impurities remain.

Home water desalination is in 4-stage to 7-stage types.

Industrial water desalination

An industrial water desalination system, also known as an industrial reverse osmosis (RO) system, is a highly effective water treatment process that can reduce 97-99% of total dissolved solids (TDS) in water for applications such as high-purity water, boiler feed, and central sterilization systems.

The industrial desalination device is utilized across many industries including pharmaceuticals, laboratories, food and beverage, oil and gas, educational institutions, universities, hospitals, hotels, and various other sectors to generate high-quality water. The dimensions and size of the industrial desalination device vary depending on the output water flow rate.

Industrial water desalination capacity

The industrial water desalination system utilizes reverse osmosis technology to improve the quality of over 2.5 cubic meters of water daily.

Industrial water desalinations come in various capacities, which depend on the type and number of membrane filters used. Membranes are available in 4-inch and 8-inch types. The minimum capacity of the industrial desalination machine is five cubic meters per day.

The water desalination device is classified into home, industrial, and commercial groups based on the device’s capacity.

For better device longevity, choose a higher capacity than your consumption.

Thermal water desalination

Over 95% of the Earth’s surface water is in the form of salt water. Various methods are employed to convert salt water to fresh water. One commonly used method for desalinating water is distillation, which is by thermal energy.

In these devices, water is boiled using very high heat, causing it to evaporate. The next step involves cooling and condensing the vapor to obtain pure water. Thermal desalination is an advanced process that requires less energy and can produce a large amount of water in a shorter period.

The main challenge of using this method is the requirement for a large amount of thermal energy. As this method relies on thermal energy, it is cost-effective only when thermal energy is readily available.

Hospital water desalination

One of the most advanced types of water desalination is the hospital water desalination. The purification process in this device includes pre-purification of water, pressurized water injection, passing through reverse osmosis filters, and disinfection of outgoing water.

Hospital water desalination serves several purposes in hospitals. For example, it sterilizes operating room equipment and purifies water for the dialysis department. The water utilized in the dialysis process must have minimal impurities, as it comes into direct contact with the blood.

Hospital water purification at the highest standard is a vital matter.

Greenhouse water desalination

The water quality used in greenhouses and the agricultural industry is crucial. If the water is not of good quality, salts in it can clog the plant’s stomata, leading to reduced growth, decreased fruit production, and ultimately, drying of the crop.

Greenhouse water desalination removes Salt, minerals, and compounds that cause water pollution. The device uses a membrane filter to filter water at a molecular level. Most water-soluble solids can not pass through this membrane, so the output water is almost pure.

In this desalination system, well water or any other water source is pumped into reverse osmosis filters to clean the water and separate the impurities. The purified water is then stored in tanks until consumption.

Portable water desalination

A portable water desalination device is small, easily portable, and designed to purify water effectively. This device has two purification filters, propylene and activated carbon, which are contained within a cartridge and function efficiently.

Portable water desalination uses reverse osmosis to convert salty water into drinking water in three stages. There are several advantages to using portable water desalination, including low energy consumption, the ability to use any water source, high speed in converting salt water into fresh water, ease of repair, and reasonable pricing. These benefits have made this type of water desalination popular among people.

Purification steps in water desalination devices

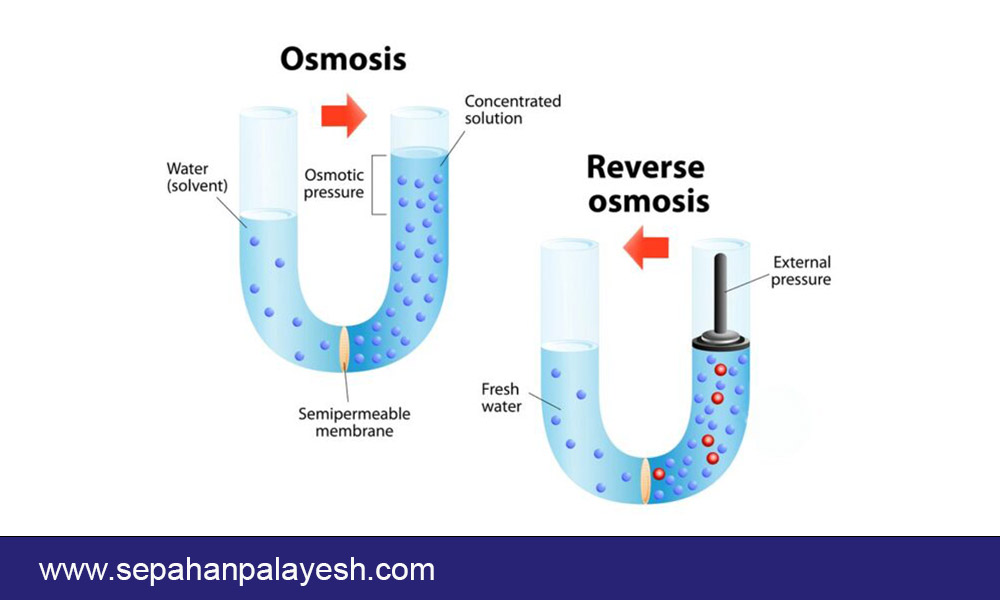

The RO device works by mimicking natural processes. In reverse osmosis water desalination, a pump into a chamber containing a semi-permeable membrane pushes the raw water. Smaller molecules can pass through the membrane, while larger molecules cannot. Therefore, only pure water can pass through the membrane, while water concentrated with impurities remains on the other side.

Water pre-treatment

Some types of contamination should be removed before entering the reverse osmosis system.

Removing these pollutants affects the quality of the final water and improves the lifespan and performance of reverse osmosis filters. During the pre-treatment, the sand filter eliminates suspended solids, while the carbon filter removes color, smell, taste, and chlorine.

Selection of high-pressure pumps for Reverse osmosis

The osmotic pressure method eliminates ions and salts, requiring pumps to provide the pressure. Appropriate filters and their arrangements can improve efficiency and reduce water wastage.

Disinfection of outgoing water

In the last stage, the water purification device removes viruses and bacteria with an ultraviolet ray filter.

Parts and spare parts of water desalination

The reverse osmosis desalination machine consists of various components and parts, each serving a specific purpose within the system:

- High-pressure pump

- Feed pump or sand filter pump

- UPVC pipes and fittings

- Pressure and low-pressure switches of the water purifier

- Various steel fittings

- Jumbo filter housing

- Membrane filter

- Steel cartridge filter housing

- Fiber/cotton filter Pressure vessel

- Activated carbon

- Reverse osmosis controller

- Fiberglass tank with sand and carbon filter

- Pressure gauge

- Sand filter valve

- Automatic sand filter valve

- Dosing pump

- Flowmeter

Disadvantages of water desalination device

- Changing filters once or twice a year.

- Failure of water flow in case of failure of one of the filters: When one filter malfunctions, the other filters will also stop working, resulting in a stoppage of water flow.

- Solar water desalination systems can be expensive. Power plants that desalinate water utilize solar collectors to heat.

- Resetting the filter pressure.

Water desalination brands

- High-pressure pumps (HP) of the reliable brand CNP, Lowara

- Sand filter pump (Feed Pump) Pentax, Leo, Lowara brands

- Dosing pump injection (dosing pump) anti-assailant Injecta, Etatron

- Upvc piping made of high-quality Pimtash Türkiye

- 304 steel piping

- Martin or Hydrotech frp tanks

- Steel or iron chassis (on customer request)

- automatic washing system cip

- Smart electrical panel suitable for the dimensions of the device

FAQ about water desalination devices

The water desalination device has two main functions: water purification through the filtration method and water desalination through the reverse osmosis method.

Desalination devices purify water in multiple stages based on the type of filter. As water flows through the device’s filters, its salts and pollutants are reduced, resulting in cleaner and purer water. Water filtration devices are less accurate and typically have a lower cost. This device operates without a tank and transfers water directly. Home desalination devices are installed on the sink or under the cabinet and do not require electricity.

The RO system, which stands for reverse osmosis, is highly effective. It includes a tank, a purification pump, and a practical filter called a membrane, which removes water impurities. This device requires access to city electricity.

A UV filter is a disinfectant filter that sterilizes water with ultraviolet light. This filter destroys the tiny organisms in the water.

There is no need to use a UV filter, but since it can eliminate fungi, bacteria, viruses, parasites, etc., it increases the water quality. In the following situations, it is better to use a UV filter:

- Well water, river water, and springwater

- In hospitals, laboratories, operating rooms, and other similar places.

- For devices that are more than five years old

Reverse osmosis is considered one of the most effective methods for water filtration. In this process, water is forced through a membrane filter under pressure, effectively purifying the water.

WQA stands for Water Quality Association, representing the global standard for high-quality water purifiers

An effluent outlet is essential for the RO home desalination device. The effluent from the water desalination machine contains a substantial amount of organic and chemical pollutants, as well as chalk and lime, and is typically cloudy. It can be used for garden irrigation. Dilution is an effective way to reuse this water.

Many factors affect the life of membrane filters, and the correct washing of filters is one of the most important. The design of the reverse osmosis water purifier is such that it can wash the filter using water pressure.

Filter replacement time is determined based on various factors like water consumption. Failing to replace the filter on time may cause it to malfunction, allowing pollutants to contaminate the water. In addition, the accumulation of sediment layers can increase pressure on the electrical parts, and the pump.

The recommended time to replace reverse osmosis filters is within the first six months. To determine the precise timing for changing the filter, observe its appearance. If the filter looks cloudy after three months of use, it should be replaced to prevent water contamination. Additionally, it is best to replace carbon block filters and powder carbon filters four months after purchase.

The water purification membrane filter can be used for up to 2 years. If the hardness of the output water is the criteria for measuring the filter’s longevity, it may even last longer than 2 years. However, the membrane filter may become damaged sooner and require replacement.

The housing is a filter housing that has an inlet and an outlet, designed with threaded entry. These threads can be made of metal or plastic.

Brass threads are stronger and less prone to erosion from frequent opening and closing, but they are expensive.

Housing with plastic thread is suitable for places that are not constantly opened and closed and have a reasonable and affordable price.

The difference in thread material does not affect the quality of water.

In all types of water purification devices, a transparent housing is used in the first stage. The fiber filter is responsible for removing sediment. Consequently, after time, it becomes saturated and needs to be replaced. Because each region has different water quality, it is impossible to determine the exact time for replacing the fiber filter. Therefore, it is better to use transparent housing in the first stage.

Cracking or breaking of the water pre-treatment hoses is the main reason for leakage in the water treatment device. Among the causes of housing breakage are as follows:

- The filter device fell, and the housing hit the ground

- The introduction of whiplash and the high pressure that water brings to the housing body

- Not replacing the filters of the lower series of the device in time

- Impacts caused by opening and closing the housing

The water hardness is determined based on various factors, with the type of membrane filter being one of the most important. A membrane filter is the primary water filter that removes water hardness.

The water filter may become blocked due to the accumulation of impurities, which can clog the system.

Resin is a polymer with an electric charge and high absorption power. Resin can remove pollutants and suspended particles with opposite electric charge. Therefore, it is known as an ion exchange resin. Also, this filter can remove calcium and magnesium ions in water and reduce water hardness.

Water pressure is exerted in two ways: inside the membrane housing and in the reverse osmosis device. The inlet water pressure is not essential. It is only necessary for the water pressure to be sufficient for the low-pressure switch to detect the water inlet and start the device. Therefore, water pressure does not affect the efficiency of the water desalination process.

The water pressure inside the device is crucial. High pressure pushes water through the membrane filter in a reverse osmosis device. Low water pressure decreases the water production rate and the membrane’s effectiveness.

Water purification devices that use reverse osmosis stop producing water as soon as their storage tank is full. If this doesn’t happen, the water will keep being produced, and pressure will build up in the tank tube, which can cause it to rupture. The high-pressure cut-off switch is between the membrane filter and the storage tank, and it’s connected to the water that comes out of the membrane housing.

There is no pressure when the tank is empty, and the device purifies the water. Once the tank is full, pressure is applied to the switch, cutting off power to the device and stopping the water purification. When the water level in the tank decreases, the pressure is released from the switch, reconnecting the power and allowing the production of purified water to continue.